Revealing Superior Top Quality Komatsu Undercarriage Parts for Boosted Machinery Performance

Revealing Superior Top Quality Komatsu Undercarriage Parts for Boosted Machinery Performance

Blog Article

Explore Undercarriage Parts for Your Equipment Requirements

Understanding the components that make up the undercarriage and the significance of choosing the best parts is crucial to making sure smooth operations and cost-efficient upkeep. As we check out the world of undercarriage components for machinery demands, a much deeper insight right into the complexities of this important system will certainly unravel, losing light on the structure that sustains the effectiveness of your tools.

Value of Undercarriage Maintenance

Normal maintenance of undercarriage parts is vital for making certain optimal performance and longevity of equipment. The undercarriage of hefty equipment, such as excavators, bulldozers, and track loaders, plays an essential duty in supporting the weight of the maker, supplying stability on various terrains, and permitting smooth procedure - komatsu undercarriage parts. Disregarding undercarriage upkeep can lead to costly repair work, reduced effectiveness, and potential safety and security dangers

Regular evaluations of undercarriage elements, such as track chains, rollers, idlers, and sprockets, are vital to recognize damage at an early stage. Dealing with problems immediately can prevent further damage to the undercarriage and other parts of the equipment. Proper cleansing of undercarriage components is additionally essential to remove dust, debris, and various other pollutants that can speed up wear and corrosion.

Regular lubrication of undercarriage parts is an additional essential facet of upkeep to make sure smooth movement and reduce rubbing in between elements. In addition, tracking the use hours and maintaining upkeep records can help in organizing prompt replacements and extending the overall life-span of the machinery. By focusing on undercarriage maintenance, tools owners can optimize efficiency, reduce downtime, and ultimately reduce repair work costs in the long run.

Kinds Of Undercarriage Parts

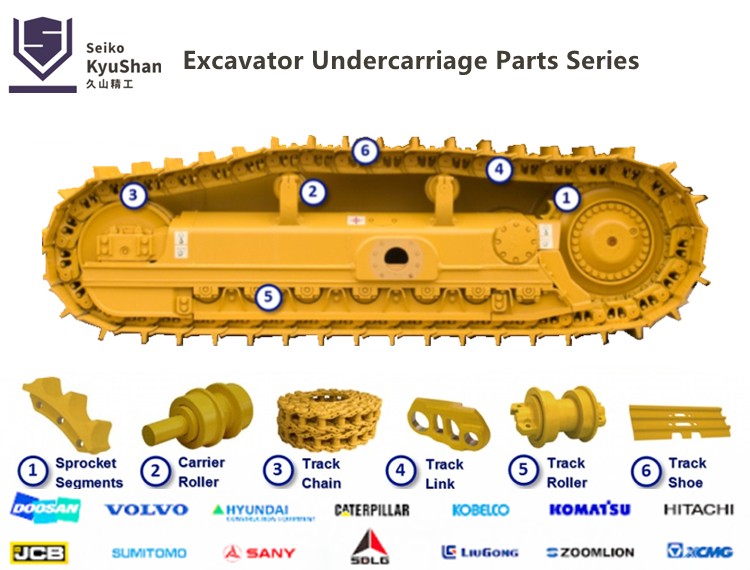

Upkeep of undercarriage components is vital for equipment durability; understanding the different kinds of undercarriage parts is essential for effective upkeep practices. Undercarriage components vary depending upon the sort of machinery and its designated use. Common kinds of undercarriage parts consist of track chains, track shoes, rollers, idlers, sprockets, and track frames.

Track chains are accountable for driving the equipment onward and sustaining the weight of the devices. Track shoes give traction and shield the track chain from wear and tear. Rollers assist in weight distribution and track support, while idlers help preserve appropriate track stress. Sprockets involve with the track chain and transfer power to move the equipment. Lastly, track structures function as the foundation for the whole undercarriage assembly, attaching all the elements with each other.

Normal inspection and upkeep of these undercarriage parts are vital to stop costly fixings and downtime. By understanding the function of each kind of undercarriage component, equipment operators can make certain optimum performance and prolong the lifespan of their tools.

Aspects to Think About When Selecting Components

Another vital factor is compatibility with the specific equipment design. Each piece of machinery might have distinct needs for undercarriage parts, including dimension, layout, and specs. Making certain that the components work with the equipment will certainly assist prevent functional concerns and early wear.

Additionally, it is important to consider the operating conditions in which the machinery will certainly be made use of. Factors such as surface, weather, and usage frequency can all affect the wear and tear on undercarriage parts. Choosing parts that are developed to stand up to the details operating conditions can assist lengthen the life of the equipment and reduce maintenance expenses over time.

Advantages of High-Quality Undercarriage Components

Top notch undercarriage components play a crucial role in enhancing machinery performance and expanding its functional longevity. One of the primary advantages of making use of top notch undercarriage parts is boosted efficiency.

In addition, top notch undercarriage parts add to set you back financial savings in the future. While the first investment might be greater contrasted to typical parts, the durability and durability of costs components decrease the need for regular replacements and fixings. This not just decreases downtime yet additionally reduces maintenance prices, ultimately bring about greater total efficiency Going Here and profitability for companies that count on heavy equipment.

In addition, premium undercarriage components improve safety and security by reducing the threat of unexpected failures or mishaps. The raised stability and efficiency provided by high-quality parts develop a much safer working setting for machinery operators and those operating in close proximity to the tools. Eventually, choosing top notch undercarriage parts is a tactical decision that generates many benefits in regards to efficiency, security, cost-efficiency, and long life.

Tips for Increasing Undercarriage Lifespan

To optimize the long life of undercarriage components for machinery, carrying out aggressive treatment practices is vital for making sure ideal performance and resilience. Frequently inspecting the undercarriage elements for indicators of deterioration, such as damaged tracks, loose screws, or damaged rollers, is important. Attending to these concerns quickly can stop further damage and expand the life-span of the undercarriage. In addition, maintaining appropriate track tension is vital to lower early endure the parts. Over-tightened tracks can cause boosted tension on the undercarriage, while loose tracks can trigger misalignment and uneven wear.

Running the equipment within advised guidelines, such as preventing excessive rates or overloading, can also contribute to extending the undercarriage lifespan. By adhering to these pointers, equipment owners can guarantee optimal efficiency and longevity of their undercarriage parts.

Verdict

In final thought, maintaining the undercarriage components of machinery is vital for optimum performance and long life. Investing in top notch undercarriage parts not only improves performance however also minimizes downtime and pricey repair work.

Routine upkeep of undercarriage components is important for guaranteeing ideal efficiency and durability of machinery.Maintenance of undercarriage parts is vital for machinery longevity; understanding the different kinds of undercarriage components is important for reliable upkeep techniques.When picking undercarriage parts for machinery, it is critical to think about various aspects to ensure ideal efficiency and long life.To make best use of the long life of undercarriage components for machinery, executing aggressive care practices is crucial for making sure ideal efficiency and durability. By adhering to these tips, machinery proprietors can make sure ideal performance and durability of their undercarriage components.

Report this page